Established in 1986,

Al Afifi Engineering & Trading Co. W.L.L

is an ISO Certified Company.

Started as a company offering Supply, Installation and Maintenance of HVAC & Refrigeration Equipments. To meet the customer demands and requirements, we started manufacturing of Cooling & Condenser Coils in 1998. Currently we are a multidiscipline Engineering, Manufacturing & Trading Company serving the HVAC sector in Qatar for the last four decades.

Our technical expertise, well qualified and experienced sales & service team and the customer focus helped us to become a reliable partner in supplying and servicing of HVAC products for many reputed organisations in Qatar.

Our Mission

Achieving high standard quality of work and services, which we render by using latest technology in its field, creativity, professional skills and carrying out its work in line with best international practices. To keep up the professional standard and practices in tasks, excellent services rendered, and complete projects assigned to us including housing but not limited to respect, honesty, transparency, and enthusiasm meanwhile employing, training, and providing equal chance to qualified candidates.

Our Vision

To be one of the leading company in its fields through the implementation of international standards, efficiency and professionalism to meet the customers’ expectations and goals. To achieve excellence in all activities carried out by the company penetrating international markets, in addition to providing comprehensive up to date solutions to various problems.

Quality Policy

It is our policy to execute its operations at all times to international standards, meeting agreed client quality requirements. Therefore, we implement a documented procedure system to ensure that Execution and Quality Control procedures are suitably drawn up in order to meet the Quality requirements, in compliance with the Contract Documents. Execution and Quality Control procedures are made available to the relevant recipients. Latest issues of applicable drawings and documents are controlled and used at all stages of the works. Activities are performed according to relevant execution procedures. Specified activities are inspected and verified according to relevant Quality Control procedures. Responsibility for each control task is clearly identified and recorded.

of

Experience

1986

Started as a small facility for HVAC Installation & Maintenance

1988

Started Cooling Coil & Heat Exchanger Manufacturing

1999

Distributor for NICOTRA Industrial Fans & Blowers in Qatar

2000

Started HVAC Filter Manufacturing (Afifi Filters)

2011

25 Years of Service in Qatar

2015

Distributor for Lionball brand Fans in Qatar

2018

Distributor for Kruger brand Ventilation fan in Qatar

2023

Started “Afifi Cooling Factory” in New Industrial Area.

Our Facility

Our Services

Installation, Commissioning, and Maintenance of HVAC Equipments

Al Afifi is a leading contractor for the supply, installation, repair, and maintenance of Air Conditioning & Refrigeration and Ventilation products in Qatar.

Installation

HVAC equipment installation involves the physical placement and connection of units within a building.This includes:

•Site preparation: Ensuring appropriate space, electrical power, and ductwork.

•Equipment handling: Careful transportation and placement of units.

•Interconnections: Connecting refrigerant lines, electrical wiring, and ductwork.

•Testing: Initial checks for leaks, electrical faults, and proper operation.

Commissioning

Commissioning is the process of verifying that the installed HVAC system operates as designed. It involves:

•System startup: Initial operation of the system under controlled conditions.

•Performance testing: Measuring system performance against design parameters.

•Balancing: Adjusting airflow to ensure even distribution throughout the building.

•Documentation: Recording system performance and configuration.

Maintenance

Maintenance involves regular inspection, cleaning, and repair to ensure optimal HVAC performance and longevity. This includes:

•Preventive maintenance: Regular checks and cleaning of filters, coils, and other components.

•Corrective maintenance: Addressing issues as they arise, such as component failures or refrigerant leaks.

•Performance monitoring: Tracking system performance to identify potential problems.

•Equipment replacement: Replacing worn-out or damaged components.

In essence, installation establishes the system, commissioning verifies its functionality, and maintenance preserves its performance over time.

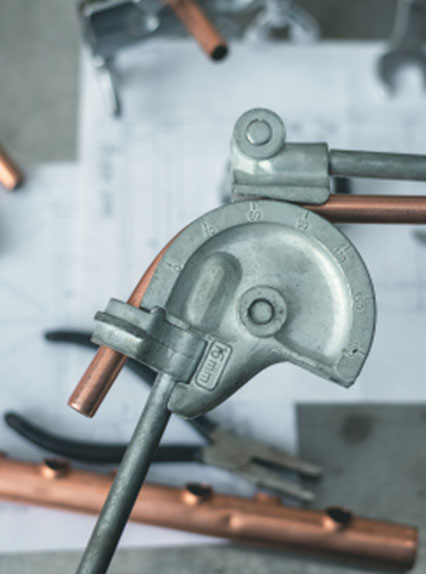

Chilled Water Pipe Fabrication, Installation and Certified Welders Fabrication

Chilled water pipe fabrication involves cutting, shaping, and joining pipe sections to create the desired piping system. This process typically includes:

• Material selection: Choosing the appropriate pipe material (copper, stainless steel, etc.) based on system requirements.

• Cutting and beveling:Precisely cutting pipe sections and preparing the ends for joining.

• Pipe fitting:Using various fittings (elbows, tees, reducers, etc.) to create the desired pipe configuration.

•Welding or joining:Connecting pipe sections and fittings using welding or other joining methods.

Installation

Chilled water pipe installation involves the physical placement and connection of fabricated pipes within a building. This includes:

•Pipe support: Installing hangers and supports to secure the piping system.

•Pipe assembly:Connecting pipe sections and fittings to form the complete piping network.

•Insulation: Applying insulation to prevent heat gain or loss and condensation.

•Testing: Conducting pressure tests and leak checks to ensure system integrity.

Certified Fabricator Welders

Certified fabricator welders are skilled professionals who have undergone rigorous training and testing to ensure their ability to produce high-quality welds. Their certifications guarantee:

•Adherence to standards:Welders follow specific welding codes and standards (e.g., ASME, AWS).

•Quality control:Consistent weld quality and reliability.

•Safety: Proper welding techniques and safety precautions.

By employing certified fabricator welders, the integrity and performance of the chilled water piping system are significantly enhanced.

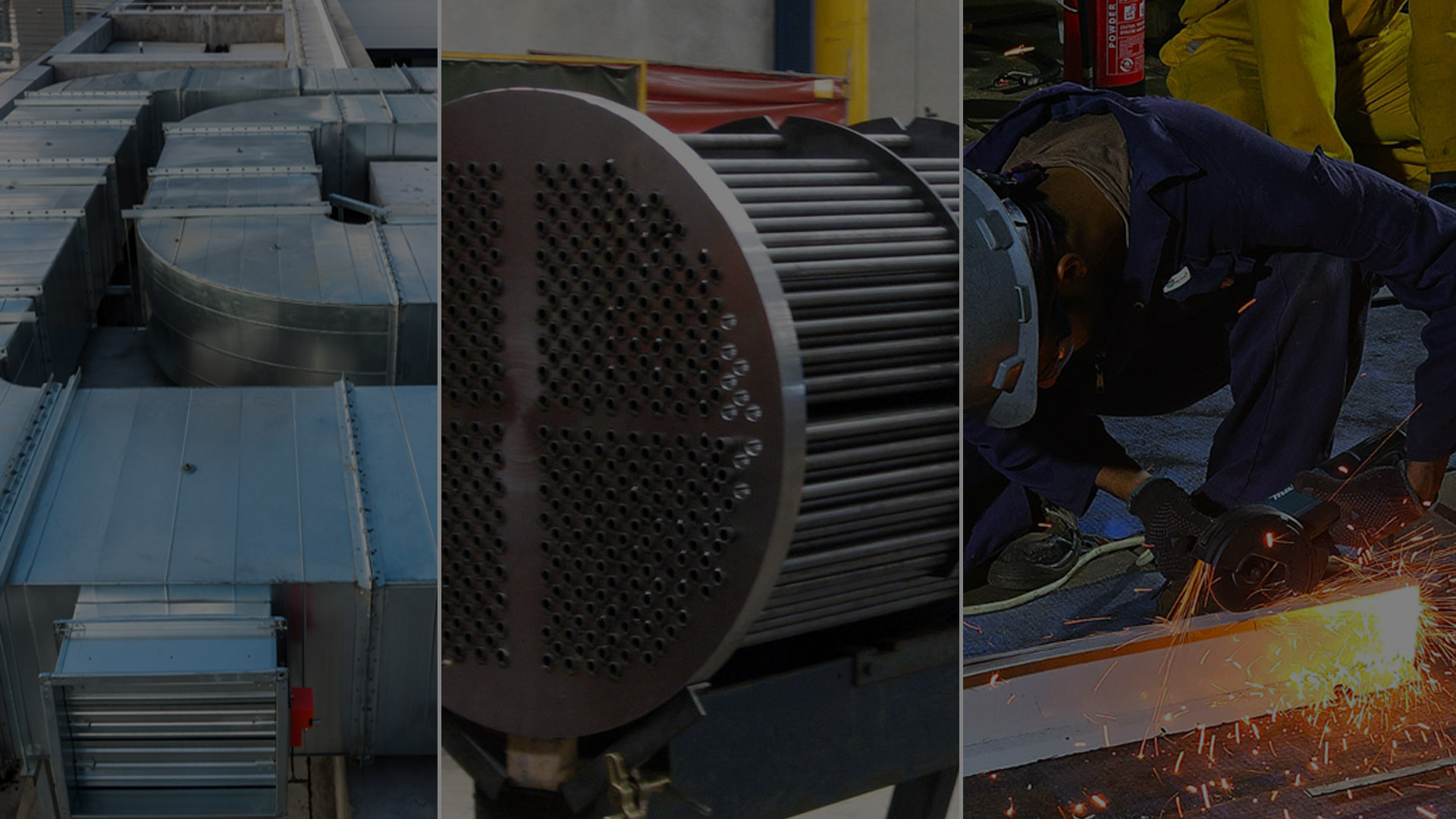

Duct Fabrication and Installation

Duct fabrication involves the creation of air ducts from sheet metal or other materials. This process includes:

•Material selection:Choosing appropriate materials based on air quality, temperature, and pressure requirements.

•Pattern development:Creating templates for duct sections.

•Cutting and forming:Shaping sheet metal into duct components.

•Joining: Connecting duct sections using welding, seaming, or other methods.

Duct installation involves the placement and connection of fabricated ducts within a building. This includes:

•Support structures:Installing hangers and brackets to secure ducts.

•Assembly: Connecting duct sections to form the complete ductwork system.

•Insulation: Applying insulation to prevent heat loss or gain and condensation.

•Air distribution components:Installing registers, diffusers, and grilles.

•Testing: Conducting air balance tests to ensure proper airflow

Industry standards standards for duct fabrication and installation are essential for ensuring system performance, energy efficiency, and safety. These standards cover:

•Material specifications:: Type, thickness, and quality of duct materials.

•Fabrication tolerances:Dimensions and shape accuracy.

•Installation methods:Proper support, sealing, and connections.

•Air leakage standards:Maximum allowable leakage to prevent energy loss and air quality issues.

•Testing and balancing:Procedures for verifying system performance.

By adhering to industry standards, ductwork systems can be designed, fabricated, and installed to optimize air distribution, energy efficiency, and indoor air quality.

Replacement of HVAC Coils, Pumps, Blowers, and Fans

These components are crucial to the operation of an HVAC system, and their replacement is often necessary due to wear and tear, damage, or inefficiency

Replacement of HVAC Coils

•Purpose: Coils transfer heat between the refrigerant and the air.

•Reasons for replacement:Corrosion, leaks, reduced efficiency.

•Process: Involves removing the old coil, cleaning the coil compartment, and installing a new coil with proper connections.

Replacement of HVAC Pumps

•Purpose: Pumps circulate water or refrigerant through the system.

•Reasons for replacement:Motor failure, seal leaks, decreased performance.

•Process: Requires disconnecting the pump, draining the system, installing a new pump, and refilling the system.

Replacement of HVAC Blowers

•Purpose: Blowers move air through the HVAC system.

•Reasons for replacement:Motor failure, imbalance, excessive noise.

•Process: Involves disconnecting the blower, removing it from the unit, installing a new blower, and balancing the system.

Replacement of HVAC Fans

•Purpose: Fans move air across the coils to facilitate heat transfer.

•Reasons for replacement:Motor failure, imbalance, reduced airflow.

•Process: Similar to blower replacement, involving removal, installation, and balancing.

Note:Replacing these components often requires specialized knowledge and tools. It's recommended to hire a qualified HVAC technician for the job to ensure proper installation and system performance.

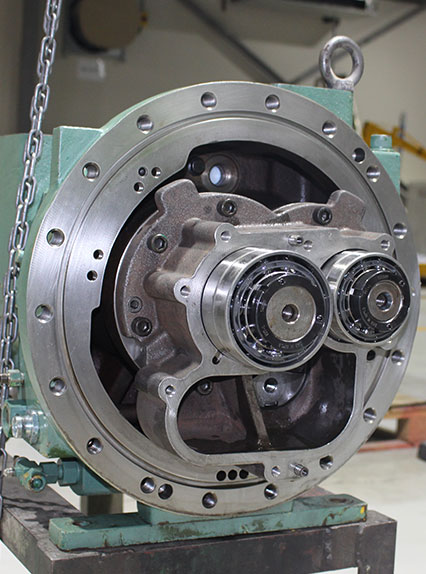

Compressor Overhauling: Light and Heavy Duty

Al Afifi is specialized in overhauling, repair, and maintenance of HVAC & Refrigeration Compressors. We provide genuine parts and offer in-house overhaul service by our highly skilled technical team who have extensive knowledge on all the leading brand compressors

Compressor overhauling is a comprehensive process to restore a compressor's performance and efficiency. The scope of the overhaul varies based on the compressor type and its condition

We Overhaul Semi-hermetic compressors, Screw (Rotary & Heli rotor) Compressors &

Open type compressors of any capacity and brands. (Bitzer, Copeland, Carrier,

Carlyle, York, Trane, McQuay etc.)

Light Duty Compressor Overhaul

Typically performed on smaller compressors used in residential or light commercial applications, it involves:

• Cleaning: Removing dirt, oil, and debris from internal components.

• Inspection:Checking for wear and tear, cracks, or other damage.

• Replacement:Replacing worn or damaged parts like seals, gaskets, and bearings.

• Reassembly:Carefully reassembling the compressor with new parts.

• Testing:Running performance tests to ensure proper operation.

Heavy Duty Compressor Overhaul

This is a more extensive process for large industrial compressors and often includes:

• Disassembly:Complete breakdown of the compressor into individual components.

• Inspection:Thorough inspection of all parts, including cylinder walls, pistons, and valves.

• Machining:Repairing or replacing worn components that require precision machining.

• Balancing:Balancing rotating components to prevent vibrations.

• Assembly:Reassembling the compressor with new or repaired parts

• Testing:Rigorous testing under various operating conditions

We can provide genuine parts and can offer an in-house overhaul service by our

highly skilled engineers, who have extensive knowledge of all the leading compressor

manufacturers and years of experience of compressor overhauls. Our overhauling

process is based on up-to-date technical information to reduce cost and time.

Re-tubing and Servicing of Heat Exchangers

Re-tubing

Heat exchanger tubes are often subjected to harsh operating conditions, leading to corrosion, erosion, or scaling. When these issues reduce the heat exchanger's efficiency, re-tubing becomes necessary. This involves:

• Removal of old tubes:Carefully extracting the damaged tubes from the tube sheets.

• Cleaning:Thorough cleaning of the tube sheets and the exchanger shell to remove debris.

• Installation of new tubes:Inserting and expanding new tubes into the tube sheets to ensure a tight fit.

•Testing:Pressure testing the re-tubed heat exchanger to verify its integrity

Servicing

Heat exchanger servicing encompasses a broader range of maintenance tasks to optimize performance and longevity:

• Cleaning:Removing fouling and deposits from both tube and shell sides to improve heat transfer efficiency.

• Inspection:Checking for leaks, erosion, corrosion, and other damage.

• Repair:Addressing issues like tube leaks, gasket replacement, or component repair.

• Testing:Conducting pressure tests and performance evaluations

Regular servicing can extend the life of a heat exchanger, prevent unplanned downtime, and reduce energy consumption.

Fabrication and Installation of Refrigerant Pipes

Fabrication of refrigerant pipes involves shaping and preparing copper or stainless steel tubing for installation in a refrigeration system. This includes

• Cutting:Precisely cutting pipes to required lengths

• Bending:Forming pipes into desired shapes using bending machines

• Flaring:Expanding the ends of pipes for creating connections

Installation involves connecting these fabricated pipes to form the refrigerant circuit. This includes:

• Pipe Support:Installing brackets and hangers to secure the pipes.

• Assembly:Joining pipe sections using fittings (elbows, tees, etc.) and brazing or soldering techniques.

• Insulation:Applying insulation to prevent heat gain/loss and condensation.

• Vacuuming:Removing air and moisture from the system before charging refrigerant.

• Pressure Testing:Checking for leaks in the refrigerant piping system.

Key considerations:

•Pipe Material:Copper is commonly used for its thermal conductivity and resistance to corrosion, while stainless steel is preferred in specific applications.

•Pipe Size:The diameter of the pipe is crucial for efficient refrigerant flow.

• Fittings:High-quality fittings are essential for preventing leaks.

• Brazing/Soldering:Proper techniques are required to ensure strong and leak-free joints.

• Safety:Handling refrigerants requires specific safety measures and certifications.

By following proper procedures and industry standards, a well-fabricated and installed refrigerant piping system ensures optimal system performance and efficiency.

Anti-Corrosive Coatings for Coils

Anti-corrosive coatings are protective layers applied to HVAC coils to prevent corrosion caused by moisture, chemicals, and other environmental factors. These coatings extend the coil's lifespan, improve efficiency, and reduce maintenance costs.

We offer different types of coatings based on the customer requirements

or application areas and corrosion environment. Hydrophilic Aluminum & Copper Fins,

anticorrosive coatings like Corro Coat & Heresite USA are available options.

Common types of coatings:

• Epoxy coatings:Offer excellent resistance to chemicals, abrasion, and corrosion.

• Electrocoatings (E-coat): Provide uniform coverage and excellent adhesion.

• Polyurethane coatings: Known for durability and resistance to UV rays.

• Acrylic coatings:Offer good corrosion protection and are often used as a base coat.

Benefits of anti-corrosive coatings

• Increased coil lifespan:Protects against corrosion and extends the coil's service life.

• Improved efficiency: Prevents fouling and scale buildup, enhancing heat transfer.

• Reduced maintenance: Less cleaning and repair are required.

• Environmental benefits: Can reduce the need for coil replacement, reducing waste.

Application methods:

• Spraying:Applying the coating evenly using a spray gun.

• Dipping:Immersing the coil in a coating bath for complete coverage.

• Electrocoating:Applying the coating through an electrical charge.

By selecting the appropriate anti-corrosive coating and application method, HVAC system owners can significantly enhance the performance and longevity of their equipment.

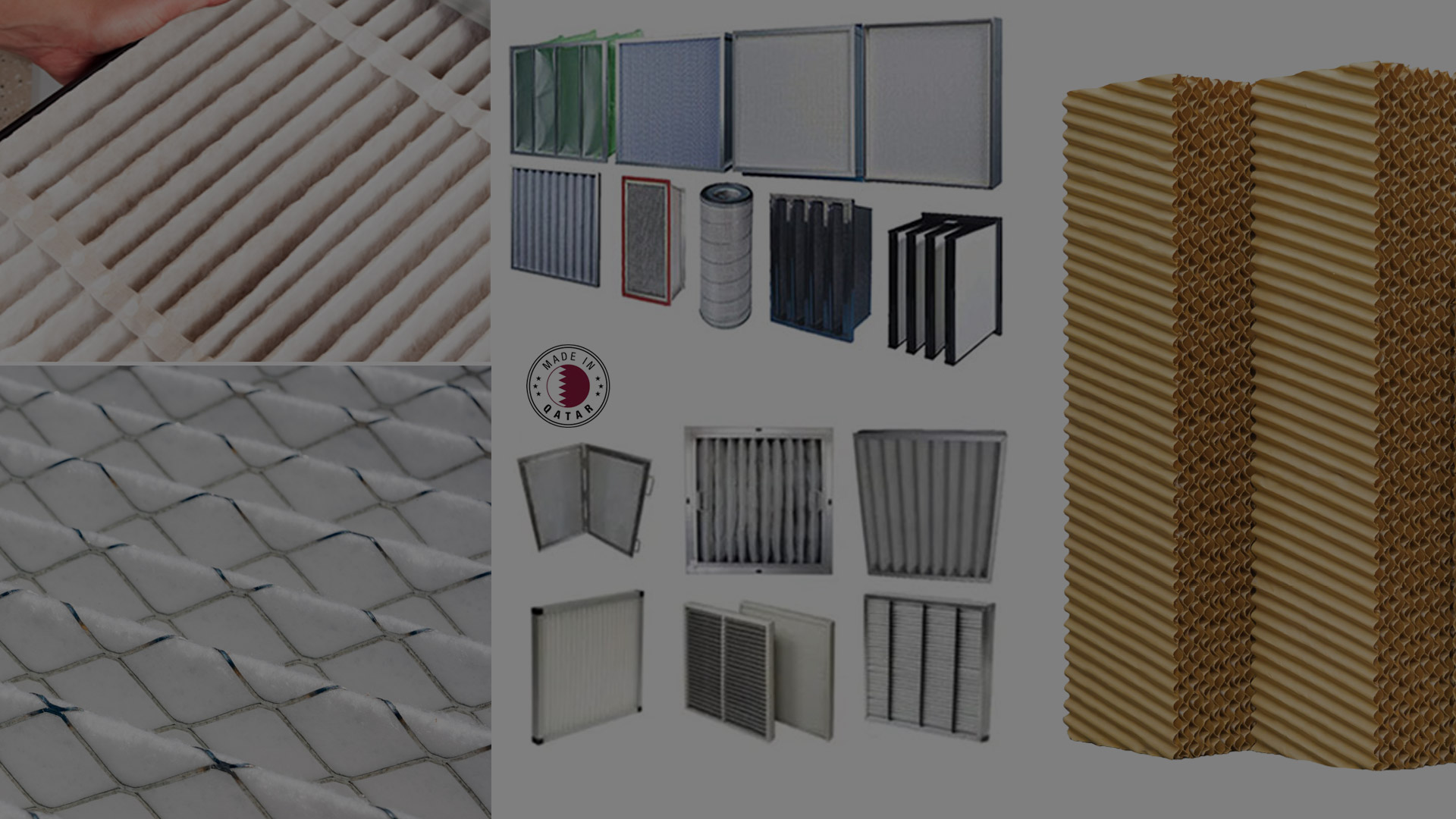

Specialised HVAC Solutions for Dairy and Poultry Farms

Al Afifi is a leading supplier for Cooling application products for Green Houses, Dairy & Poultry farms in Qatar.

Dairy factories and farms, as well as poultry farms, require specific HVAC systems due to their unique environmental needs. We are a registered supplier for Evaporative Cooling Pads, Axial Fans etc for the above applications.

Dairy Factories and Farms

•Milk Quality Preservation: The primary goal is to maintain optimal temperature and humidity for milk quality.

•Hygiene and Sanitation: HVAC systems must prevent microbial growth and maintain clean air conditions.

•Energy Efficiency: Considering the large spaces and continuous operation, energy-efficient systems are crucial.

•Solutions:

oPrecision temperature and humidity control systems.

oHigh-efficiency air filtration to remove contaminants.

oStainless steel components for easy cleaning and sanitation.

oHeat recovery systems to reduce energy consumption.

Poultry Farms

•Temperature and Humidity Control: Maintaining optimal conditions for bird health and egg production.

•Ventilation: Ensuring adequate air exchange to prevent disease spread.

•Odor Control: Managing ammonia and other harmful gases.

•Solutions:

oPrecise temperature and humidity control systems with rapid response.

oHigh-volume ventilation systems with efficient air distribution.

oAir filtration systems to remove dust and pathogens.

oOdor control systems using carbon filters or other technologies.

Key Considerations for Both:

•Biosecurity: Preventing the spread of diseases through strict air filtration and ventilation.

•Corrosion Resistance: Using materials resistant to harsh environments (e.g., ammonia, moisture).

•Reliability: Ensuring continuous operation for uninterrupted production.

•Energy Efficiency: Implementing energy-saving technologies to reduce costs.

By tailoring HVAC systems to the specific needs of dairy and poultry facilities, it's possible to optimize production, improve animal welfare, and enhance product quality.

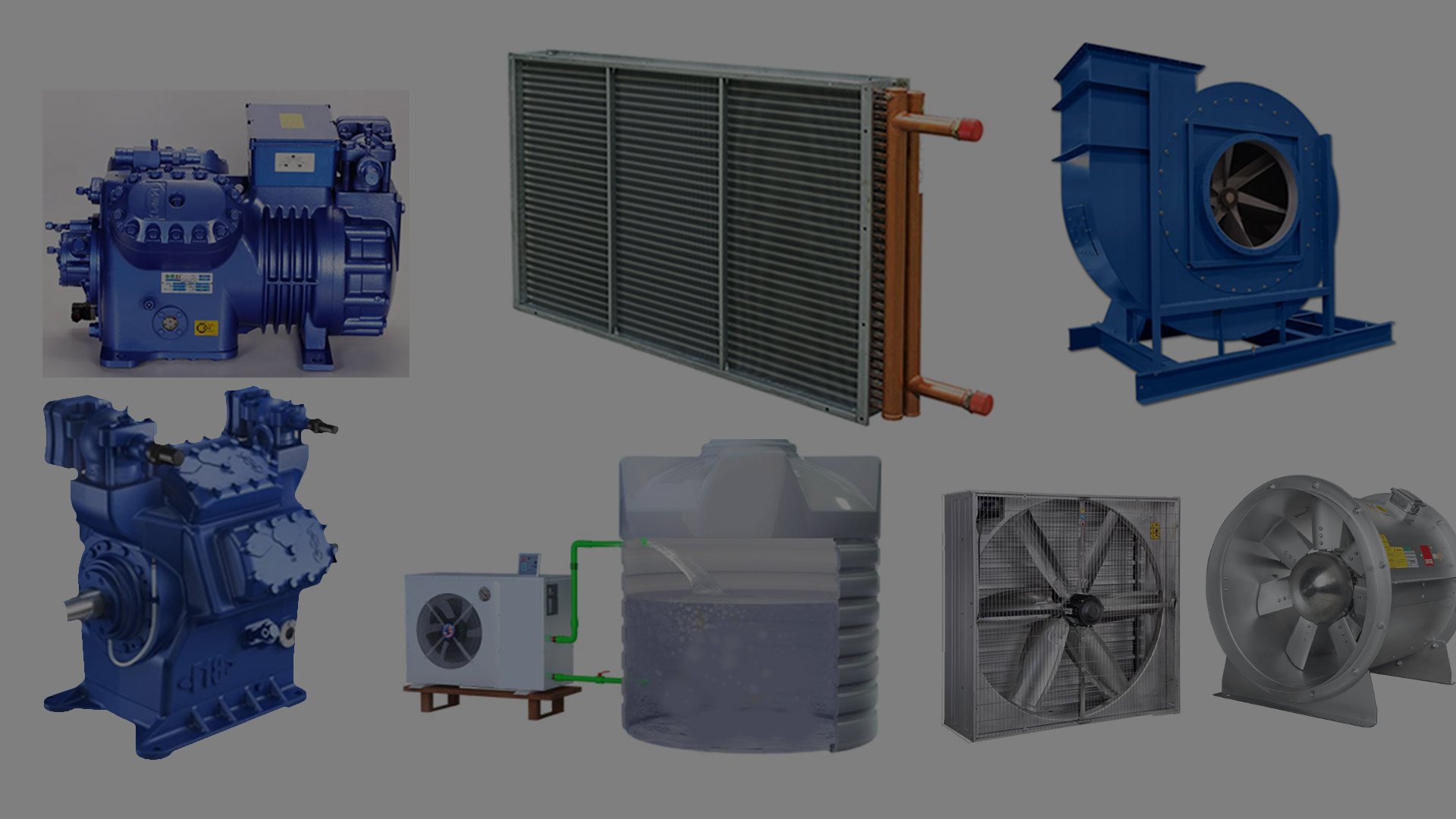

Our Products

HVAC & Refrigeration Products

Al Afifi deals with all the leading brands of HVAC, Refrigeration and Ventilation products as per the application and customer requirements in Qatar.

Key HVAC Equipment:

•Heating Equipment:Furnaces, boilers, heat pumps

•Cooling Equipment:Air conditioners, chillers.

•Ventilation Equipment:Connecting refrigerant lines, electrical wiring, and ductwork.

•Air Cleaning Equipment:Filters, air purifiers.

•Humidity Control Equipment: Dehumidifiers, humidifiers.

How they work together:

• Heating: Warms the air using a heat source like gas, oil, or electricity.

• Cooling: Removes heat from the air using refrigeration cycles.

• Ventilation: Circulates fresh air and removes stale air.

• Air Cleaning: Filters out impurities and contaminants.

• Humidity Control: Regulates moisture levels for comfort.

Types of HVAC Systems:

• Central systems: Handle heating and cooling for entire buildings.

• Split systems: Separate indoor and outdoor units.

• Ductless systems: Deliver conditioned air directly without ductwork

• Mini-split systems: Multiple indoor units connected to a single outdoor unit.

HVAC Filtration Products

HVAC systems use various filters to clean the air. Al Afifi is a leading manufacturer and supplier of Air Filters for HVAC applications in Qatar. Our product range includes Aluminium Filters, Synthetic Flat & Pleated Filters, Bag Filters, HEPA Filters, Activated Carbon Filters, V-Bank Filters, and Aluminium & Synthetic Media Rolls etc. We offer filters from lower efficiency to high efficiency to meet the application requirement of our customers.

Common Types of HVAC Filters:

•Panel Filters:Disposable filters made of fiberglass or synthetic materials

•Pleated Filters:Offer increased surface area for better filtration efficiency.

•Extended Surface Filters:High-efficiency filters with a large media area.

•HEPA (High-Efficiency Particulate Air) Filters:Capture nearly 99.97% of airborne particles.

•Carbon Filters:Absorb odors and gases.

Factors Affecting Filter Selection:

• MERV Rating:Measures filter efficiency in capturing particles.

• Particle Size:Determines the type of filter needed.

• Indoor Air Quality Requirements:Specific needs for homes, offices, or industrial settings.

• HVAC System Capacity:Filter size and type should match the system

By selecting the right HVAC filtration products, you can create a healthier indoor environment and extend the life of your HVAC system.

Cooling Coils for Air Conditioning & Refrigeration Systems

Al Afifi is a leading HVAC Coil manufacturer in Qatar specialised in Anti Corrosive coated coils. We manufacture and supply cooling coils in different sizes using 5/16”, 3/8”, 1/2” & 5/8” OD Copper tubes. The Fins are manufactured as per customer requirements either in Aluminium or Copper

Cooling coils are essential components in both air conditioning and refrigeration systems. They are responsible for heat exchange, transferring heat from one medium to another.

We offer different types of coatings based on the customer requirements

or application areas and corrosion environment. Hydrophilic Aluminum & Copper Fins,

anticorrosive coatings like Corro Coat & Heresite USA are available options.

How Cooling Coils Work

•Refrigerant Coils:These coils contain refrigerant that evaporates as it absorbs heat from the air. This process cools the air.

•Water-Cooled Coils:These coils use chilled water to cool the air. The water absorbs heat from the air and is then cooled in a separate chiller.

Types of Cooling Coils

• Evaporator Coils:Used in air conditioners and refrigerators to cool the air.

• Condenser Coils:Used to release heat from the refrigerant into the environment.

• Coil Materials: Copper, aluminium, and stainless steel are common materials.

Key Functions

• Cooling:Lowering the temperature of air or liquid

• Dehumidification:Removing moisture from the air.

• Heat Transfer:Efficiently transferring heat from one medium to another.

Proper maintenance of cooling coils is essential for optimal system performance and energy efficiency.

Industrial Fans & Blowers

Al Afifi is an authorized supplier of Nicotra Gebhardt, Kruger, Lionball & CKS brand HVAC Blowers and Ventilation fans in Qatar. The range of products include.

• Blower assembly for Package Units, Air Handling Units & Fan Coil Units.

• Centrifugal and Axial Fans

• Roof Mounted Propeller Fans/span>

• Energy Recovery Products

• Kitchen Ventilation Products

• Fans for Green Houses, Poultry & Dairy Farms. Industrial fans and blowers are critical components in various industrial processes, providing airflow for ventilation, cooling, drying, and material handling.

Types of Industrial Fans and Blowers:

• Axial Fans:These fans have blades arranged parallel to the airflow axis and are suitable for high airflow, low-pressure applications

• Centrifugal Fans:These fans use centrifugal force to increase air pressure and are ideal for medium to high-pressure applications.

• Blowers:Similar to centrifugal fans but designed for higher pressures and smaller airflow volumes.

Applications:

• Ventilation:Removing polluted air, smoke, and fumes.

• Cooling:Reducing equipment or process temperatures.

• Drying:Removing moisture from materials.

• Material Handling:Conveying materials like dust, grains, and powders.

• Pressure Boosting:Increasing air pressure for various processes.

Key Considerations:

• Airflow:The volume of air moved.

• Pressure:The force exerted by the fan or blower.

• Efficiency:The ratio of output power to input power.

• Noise Level:The sound generated by the equipment.

• Material Compatibility:The fan or blower's ability to handle specific materials.

By understanding the specific requirements of an application, the right industrial fan or blower can be selected to optimize performance and efficiency.

HVAC Compressors & Spares

Al Afifi is a leading supplier specialized in overhauling, repair, and maintenance of HVAC & Refrigeration Compressors. We provide genuine parts and offer in-house overhaul service by our highly skilled technical team who have extensive knowledge on all the leading brand compressors.

The heart of an HVAC system, compressors are responsible for compressing refrigerant, a crucial step in the cooling cycle. They convert low-pressure, low-temperature refrigerant into high-pressure, high-temperature refrigerant.

Types of Compressors:

•Reciprocating:Use pistons to compress refrigerant

•Rotary:Employ a rotating element to compress refrigerant.

•Screw:Utilize intermeshing screws to compress refrigerant.

•Scroll:Employ two spiral-shaped elements to compress refrigerant.

HVAC Compressor Spares

Compressor spares are essential for maintaining and repairing HVAC systems. Common spare parts include:

• Compressor Motors:The driving force behind the compressor.

• Pistons, Rods, and Bearings:Internal components for reciprocating compressors

• Rotors, Blades, and Seals:Components for rotary, screw, and scroll compressors.

• Valves and Controls:Regulate refrigerant flow.

• Electrical Components:Relays, starters, and other electrical parts.

Regular maintenance and replacement of worn-out compressor parts are crucial for optimal system performance and energy efficiency.

HVAC Installation Materials & Accessories

HVAC installation requires a variety of materials and accessories to ensure efficient and safe operation. Some common materials include:

•Copper and steel pipes:For refrigerant lines.

•Insulation:To prevent heat loss and condensation.

•Ductwork:For air distribution.

•Electrical wiring and components:For power supply and control.

•Fasteners:For securing components.

• Sealants and adhesives:For creating airtight and watertight connections

Anti-vibration Pads

Anti-vibration pads are essential accessories used to isolate HVAC equipment from vibrations. They are placed between the equipment and its supporting structure to reduce noise and prevent equipment movement.

Benefits of anti-vibration pads:

• Noise reduction:Significantly decreases equipment noise

• Vibration isolation:Protects equipment and extends its lifespan.

• Stability:Prevents equipment movement and potential damage.

By using appropriate installation materials and accessories, including anti-vibration pads, HVAC systems can operate efficiently and quietly.

Roof Tank Water Chillers

Al Afifi manufactures and supply uniquely designed Roof Tank Water Coolers. This is used for cooling roof top water storage tanks during summer when the ambient temperature is high. Afifi Cool roof tank water coolers are widely used in domestic application (Villas & Apartments) & commercial buildings in Qatar.

•Capacities available from 1.5 – 3.0TR

Roof tank water chillers are devices designed to cool the water stored in rooftop tanks. These tanks often supply water for domestic use in buildings, especially in regions with hot climates.

How they work:

•Cooling process:The chiller uses a refrigeration cycle to extract heat from the water in the tank, lowering its temperature.

•Components:Typically includes a compressor, condenser, evaporator, and a water pump.

•Installation:Mounted near the roof tank, with pipes connecting the chiller to the tank.

Benefits:

•Improved water quality:Provides cooler shower water during hot weather

•Energy efficiency:Some models offer energy-saving features.

•Increased comfort:Provides cooler shower water during hot weather.

Image of a roof tank water chiller:

By maintaining a cooler water temperature in the roof tank, these chillers enhance water quality and comfort for building occupants

We Manufacture

HVAC Filtration Products

HVAC systems use various filters to clean the air. Al Afifi is a leading manufacturer and supplier of Air Filters for HVAC applications in Qatar. Our product range includes Aluminium Filters, Synthetic Flat & Pleated Filters, Bag Filters, HEPA Filters, Activated Carbon Filters, V-Bank Filters, and Aluminium & Synthetic Media Rolls etc. We offer filters from lower efficiency to high efficiency to meet the application requirement of our customers.

Common Types of HVAC Filters:

• Fiberglass Filters:Cheap, disposable, but offer minimal filtration.

•Pleated Filters:More efficient than fiberglass, capturing larger particles like dust and pollen.

•Electrostatic FiltersWashable and reusable, capturing particles through static charge

•HEPA Filters:High-efficiency, capturing almost all airborne particles, including bacteria and viruses.

• Carbon Filters: Absorb odors and gases.

• UV Filters: Kill bacteria and viruses using ultraviolet light.

• Electronic Air Cleaners: Use electrostatic charges to remove particles.

Key Factors::

• MERV Rating: Measures filter efficiency in capturing particles of different sizes.

• Filter Size: Matches the HVAC system for proper airflow.

• Indoor Air Quality Needs: Determine the appropriate filter type based on allergies, asthma, or other concerns.

Note: Regular filter replacement is crucial for maintaining indoor air quality and HVAC system efficiency.

Condenser and Evaporator Coils

Al Afifi is a leading HVAC Coil manufacturer in Qatar specialised in Anti Corrosive coated coils. We manufacture and supply cooling coils in different sizes using 5/16”, 3/8”, 1/2” & 5/8” OD Copper tubes. The Fins are manufactured as per customer requirements either in Aluminum or Copper.

We offer different types of coatings based on the customer requirements

or application areas and corrosion environment. Hydrophilic Aluminum & Copper Fins,

anticorrosive coatings like Corro Coat & Heresite USA are available options.

Evaporator Coil

•Location: Inside the indoor unit.

•Function: Absorbs heat from indoor air. Refrigerant flowing through the coil evaporates, taking heat with it.

•Process: Warm indoor air passes over the coil, cooling down as the refrigerant absorbs heat.

Condenser Coil

•Location: Outside the home, in the outdoor unit.

•Function: Releases heat absorbed by the evaporator coil into the outdoor air.

•Process: Refrigerant, now hot, flows through the coil. A fan blows outdoor air over the coil, cooling the refrigerant and releasing heat into the environment.

In essence:

•The evaporator coil cools your indoor air.

•The condenser coil releases the heat outside.

Both coils are crucial for the efficient operation of your HVAC system.

Shell and Tube Heat Exchangers

Al Afifi manufactures and repairs all kinds of Shell & Tube Heat Exchangers. We have the expertise and tools for maintenance and re-furbishing all types of heat exchangers.

A shell and tube heat exchanger is a device used to transfer heat between two fluids. It consists of a cylindrical shell containing a bundle of tubes.

•One fluid flows through the tubes.

•The other fluid flows outside the tubes, within the shell.

Heat is transferred between the two fluids through the tube walls.

Key components:

•Shell: The cylindrical outer casing.

•Tube bundle: A group of tubes within the shell.

•Baffles: Plates inside the shell to direct fluid flow and enhance heat transfer.

Common applications:

•Power plants

•Oil refineries

•Chemical processing

•HVAC systems

Note: Our Customer base includes Marine, Power Plants & Petrochemical (Oil & Gas) organisations.

Roof Tank Water Chillers

Al Afifi manufactures and supply uniquely designed Roof Tank Water Coolers. This is used for cooling roof top water storage tanks during summer when the ambient temperature is high. Afifi Cool roof tank water coolers are widely used in domestic application (Villas & Apartments) & commercial buildings in Qatar.

•Capacities available from 1.5 – 3.0TR

Key components of a water chiller include:

•Compressor: Compresses refrigerant to increase its temperature and pressure.

•Condenser: Cools the high-pressure refrigerant, releasing heat into the environment (often using water or air).

•Evaporator: Lowers the refrigerant's temperature, absorbing heat from the water being cooled.

•Expansion valve: Controls the flow of refrigerant.

Our Clients

|

|

|

|

|

|

|

.png) |

.jpeg) |

.jpeg) |

.jpeg) |

|

.png) |

|

.jpeg) |

|

|

|

|

.png) |

|

.png) |

.jpeg) |

.png) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contact Us

Al AFIFI

Engineering & Trading Co. W.L.L

Cooling Factory

Building Number 153

Zone 81, Street 13

Small & Medium Industrial Area

Doha, Qatar

PO Box: 15359

Telephone: +974-4460 6228

Fax: +974-4460 6229

Email: ac@afifiqatar.com

Email: sales@afifiqatar.com

Working Hours: 7am – 12pm and 1pm – 4pm